Effective Management of Gas Distribution and Flow

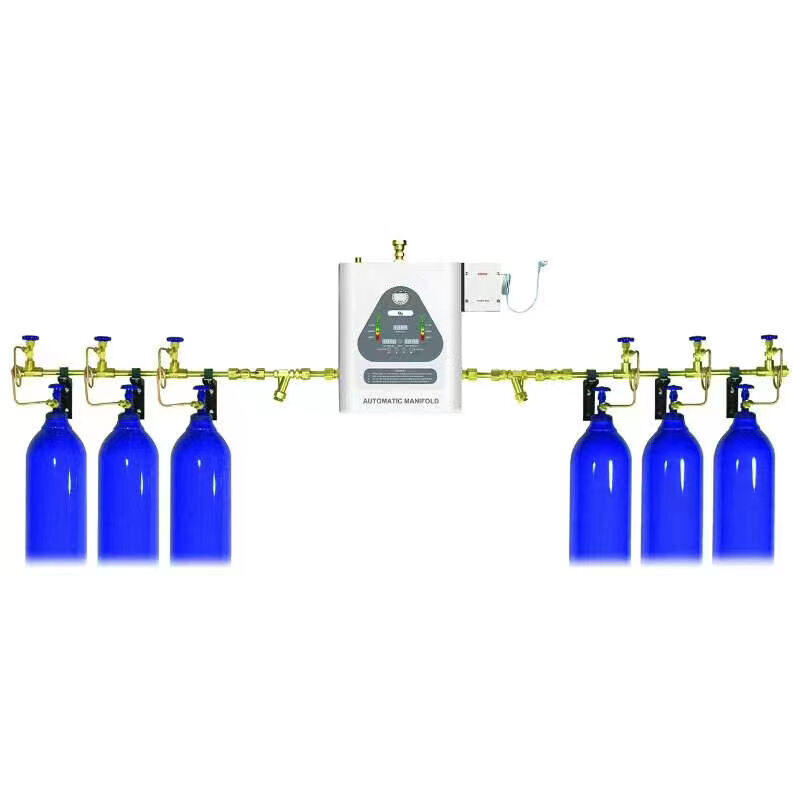

Our medical gas manifolds allow for effective distribution and flow control of gas. The architecture is designed to mitigate pressure losses that would normally occur when distributing medical gases through multiple outlets. Due to a sophisticated arrangement of channels and valves, these manifolds can provide oxygen and air to multiple medical equipment and patient care stations simultaneously. As an example, in a hospital ward, the manifold can provide smooth, uninterrupted delivery of oxygen to every patient bed while delivering medical air to the adjacent respiratory equipment. Gas flow rates can be finely tuned using advanced flow control valves, ensuring that healthcare personnel can optimally allocate the gas delivered for various medical interventions and patients, which in turn enhances the efficiency of utilizing medical gases.