Customizable Solutions for Diverse Requirements

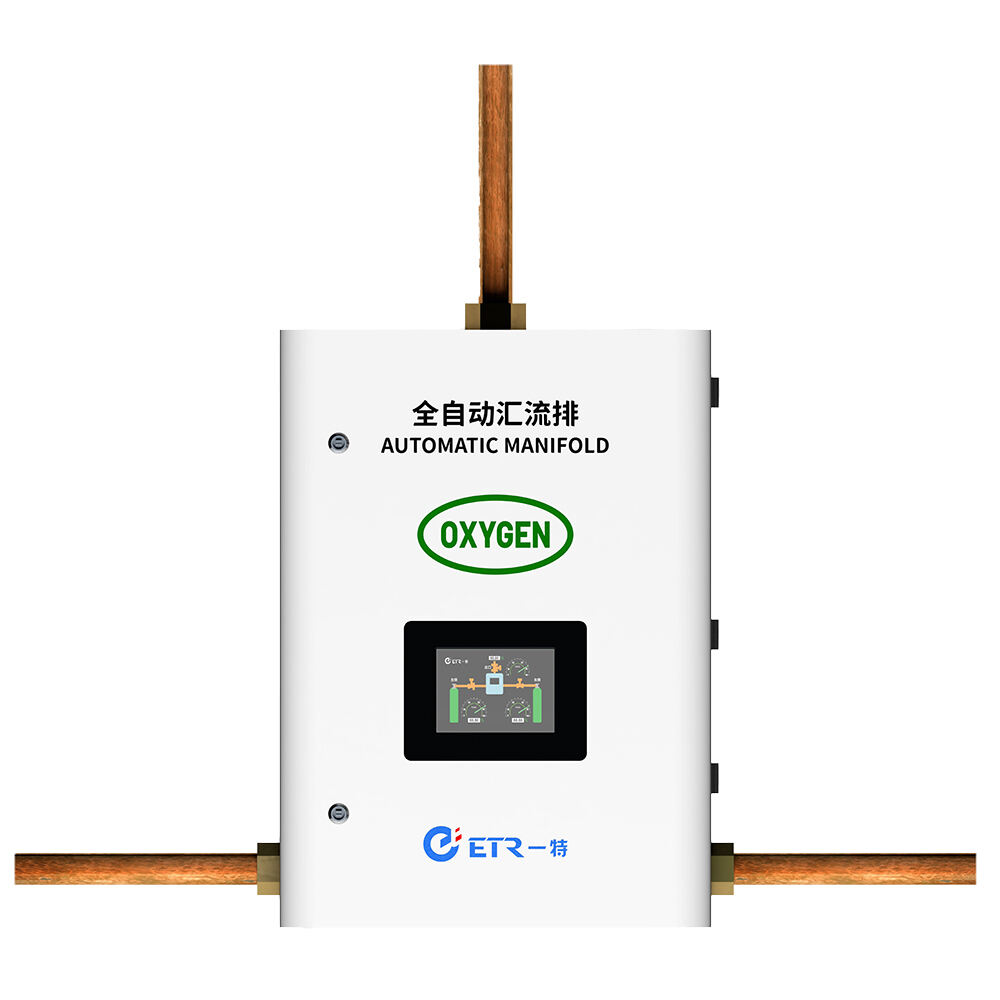

We know that there are various kinds of healthcare facilities, and each one has its specific needs when it comes to medical gas systems. Eter Medical of Hunan offers customized solutions for medical gas manifolds. Depending on the adjustable layout and gas usage patterns of each facility, our experts can customize the manifolds’ dimensions, outlet counts, gas connections, and extra features. We can create multi-channel manifolds with advanced control systems for large hospitals and multi-faceted gas distribution requirements. Smaller clinics can make do with simplified, compact designs. Additionally, other customization options include sensors for monitoring, regulating pressure, and alarm systems built directly into the manifold that guarantee absolute customization for every healthcare setting.