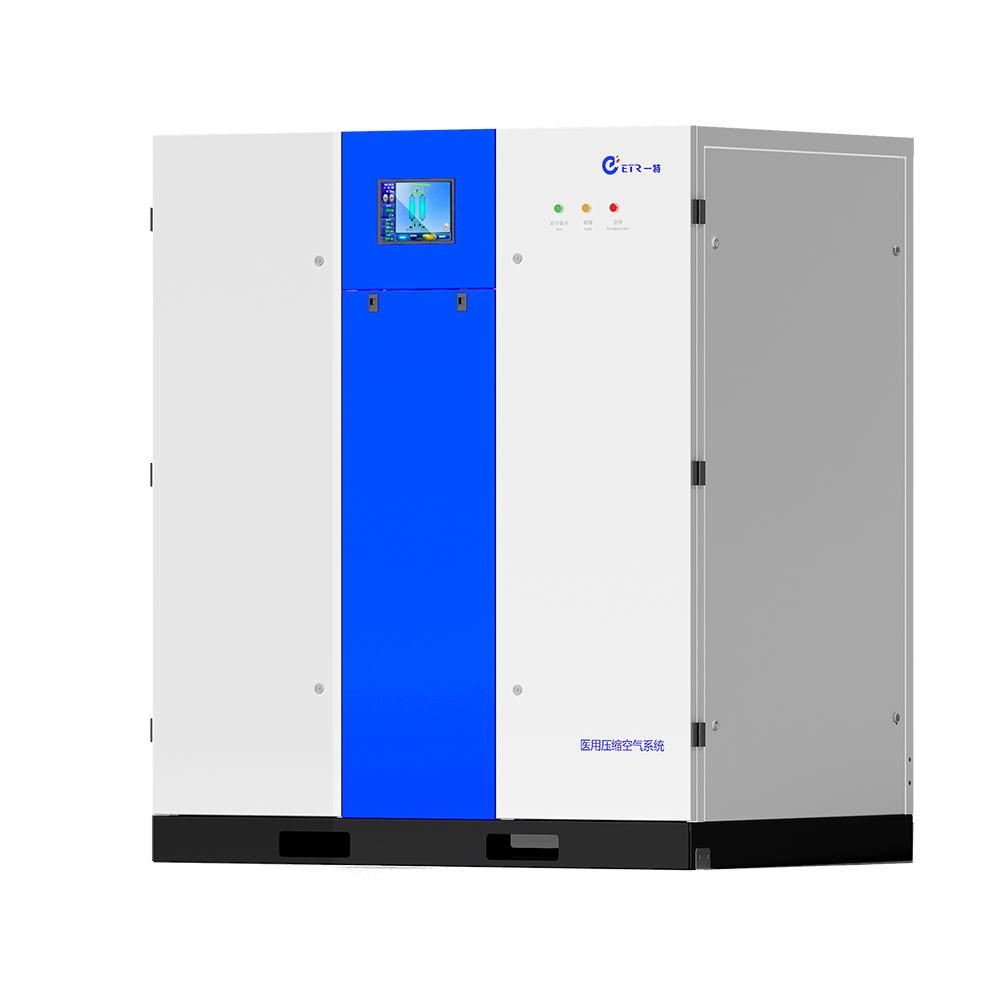

Intelligent Monitoring and Control System

Our off-the-shelf Compressed Air Systems come equipped with monitoring and control systems that are highly intelligent. It has sensors which monitors critical parameters like pressure, temperature, flow rate, and air quality continuously and provides data in real-time. This data is transmitted to a central control unit which can be accessed remotely through a simple interface. Users can monitor diagnostics of the system, receive notifications about abnormal functioning of the system, and adjust some parameters remotely. If the air quality is poor or the pressure goes below a predefined range, then the system is able to, and will, automatically trigger alarms. The air supply may also be adjusted automatically to meet certain demand levels. Also additional compressors may be started and backup filters activated automatically using advanced control strategies. These intelligent systems makes the entire operation of the compressed air system because it minimizes interventions from personne