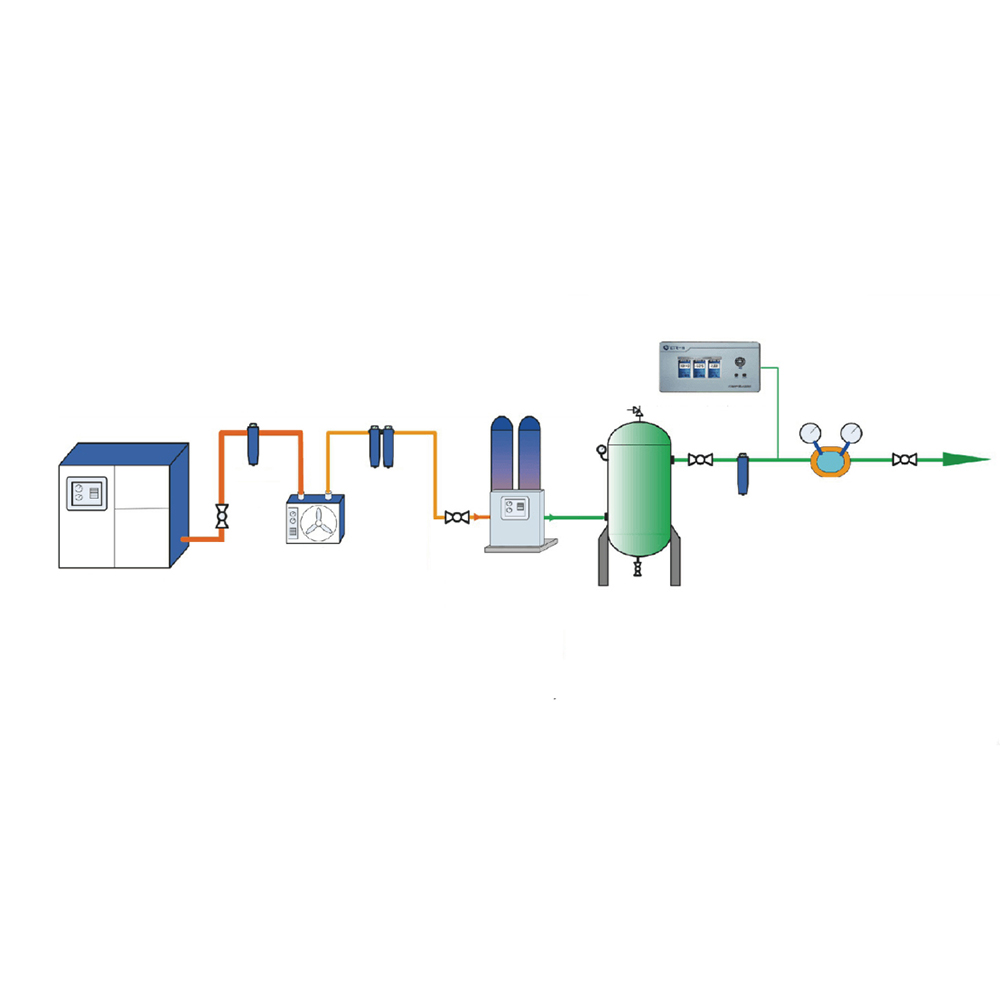

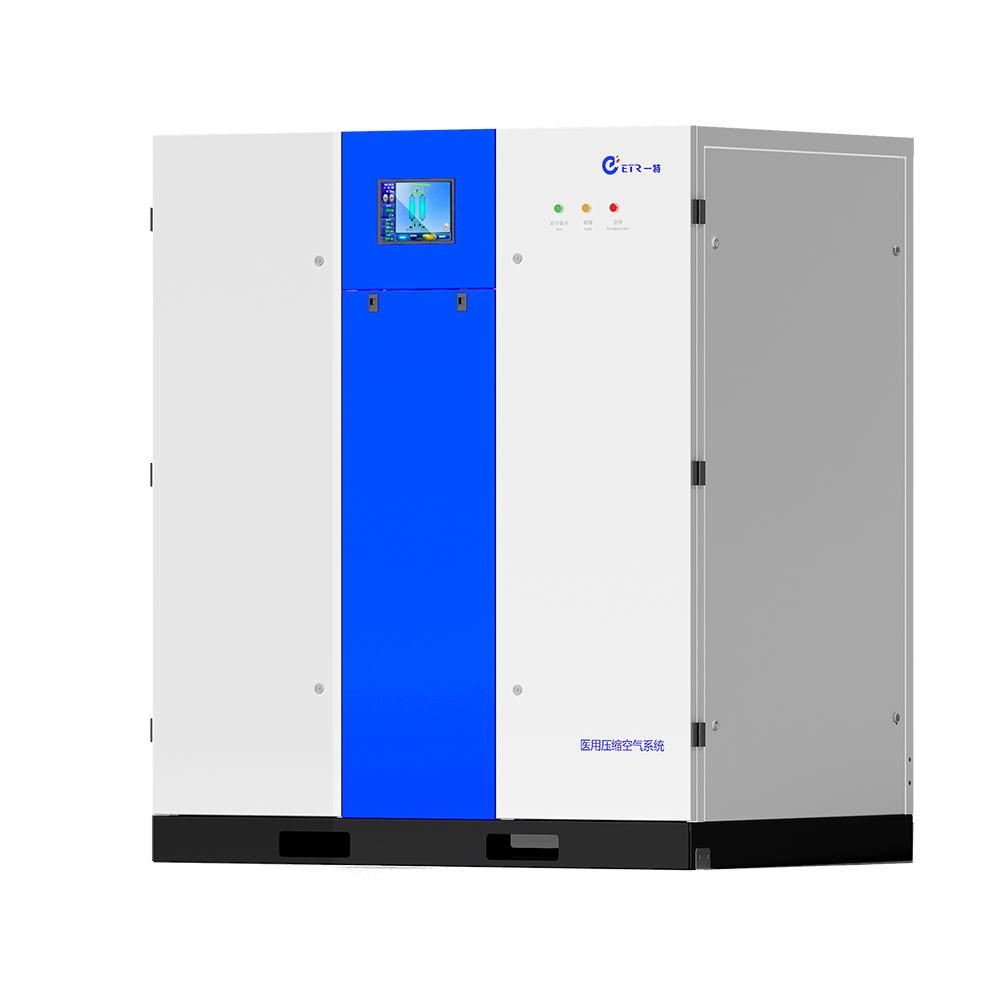

Hunan Eter Medical's air compressor stations are complete and fully integrated systems specially designed to satisfy the varying requirements of compressed air supply in different industries, particularly in healthcare. These stations are a synthesis of a highly advanced set of air compressors, air treatment devices, storage tanks, and control systems. The performance of the selected compressors guarantees the adequate and stable supply of compressed air. Cost-effectiveness is achieved with the incorporation of energy saving technologies that minimize power consumption. Smart management systems enable timely evaluation of the performance in terms of pressure, flow, and energy consumption. In the healthcare facilities, these stations ensure the provision of clean and dependable compressed air which is vital for the proper functioning of medical equipment and smooth execution of medical procedures. These air compressor stations can be configured to meet the specific needs of each customer, providing effective and adaptable solutions for the supply of compressed air.