Medical Gas Pipeline Systems: Vital Components for Healthcare

Essential Functions in Patient Care

The medical gas pipeline system is absolutely essential in hospitals and clinics across the country. These networks deliver important gases like oxygen and laughing gas directly to operating rooms, recovery areas, and emergency departments throughout medical facilities. When everything works right, patients get what they need when they need it most. Take ICU patients who require continuous oxygen flow during procedures - even a brief interruption could lead to serious complications or worse. Managing these complex systems well isn't just about keeping things running smoothly; it actually saves money too. Hospitals that track their gas consumption patterns often find ways to cut down on waste without compromising quality of care. Some facilities report saving thousands annually simply by fixing leaks and optimizing delivery rates, all while making sure every breath matters for those counting on these lifelines.

Core System Components Explained

A medical gas system works best when all its main parts are functioning properly. These parts basically consist of pipes, valves, and pressure controls. Together they distribute oxygen and other gases safely around hospitals and clinics. Every single part needs to meet strict safety rules so there won't be any dangerous leaks or malfunctions that might put patients at risk. When hospital staff really understand how these different parts connect and interact, they can plan better for regular checks and know when it's time for replacements or improvements. Maintenance isn't just routine work either it involves checking connections, testing alarms, and making sure everything stays within safe operating parameters. This kind of attention keeps patients safe and helps doctors do their jobs without worrying about equipment failures.

Oxygen Generator Integration

When hospitals install oxygen generators directly into their medical gas pipelines, they gain a dependable source of oxygen without needing to rely so much on outside suppliers. These systems give facilities more control over their oxygen needs while cutting down on the expenses tied to regular gas deliveries, which makes them pretty good investments financially speaking. Setting up these kinds of systems isn't something that happens overnight though. It takes careful planning and following all sorts of safety rules to make sure everything works well with what's already there. The way oxygen generators fit into the overall medical gas setup matters a lot for how reliable and efficient the whole thing becomes. As we've seen during recent health crises, when demand for medical gases spikes suddenly, hospitals with strong internal oxygen production capabilities respond much better to emergencies and maintain patient care standards even under pressure.

Designing Effective Medical Gas Distribution

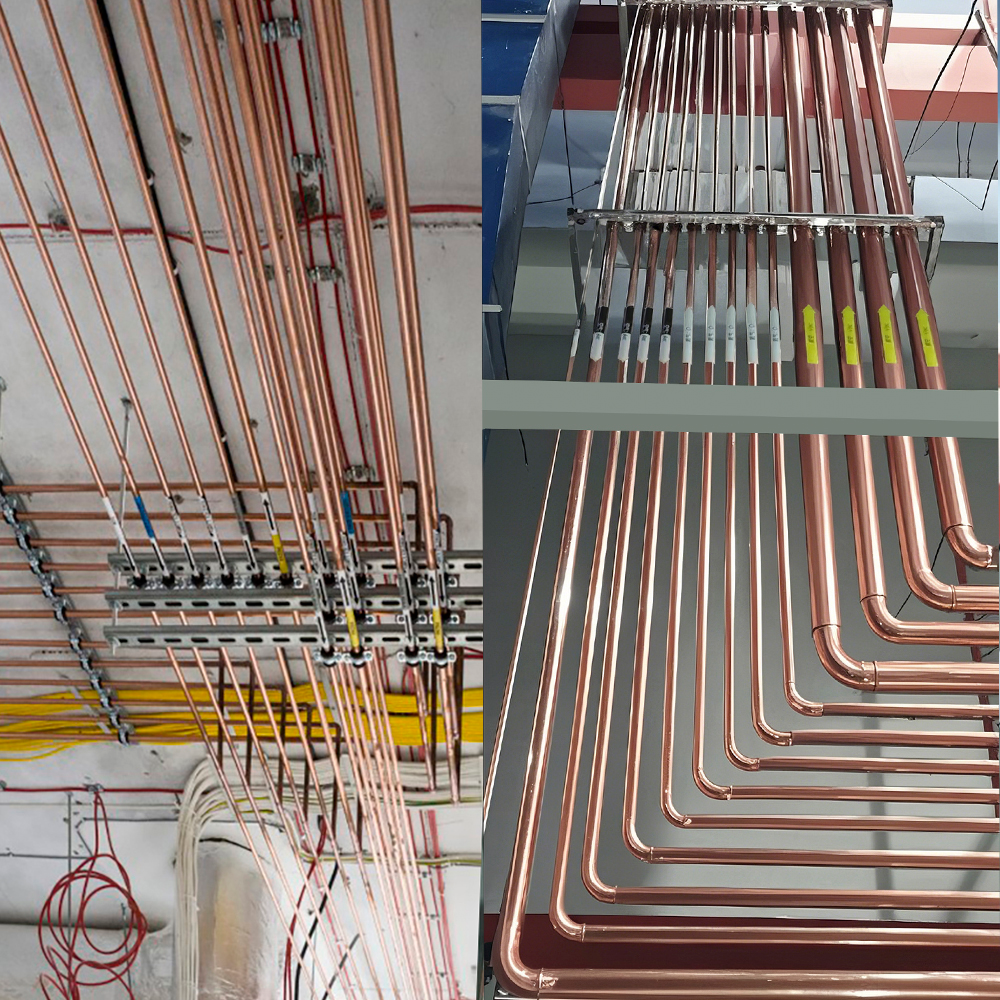

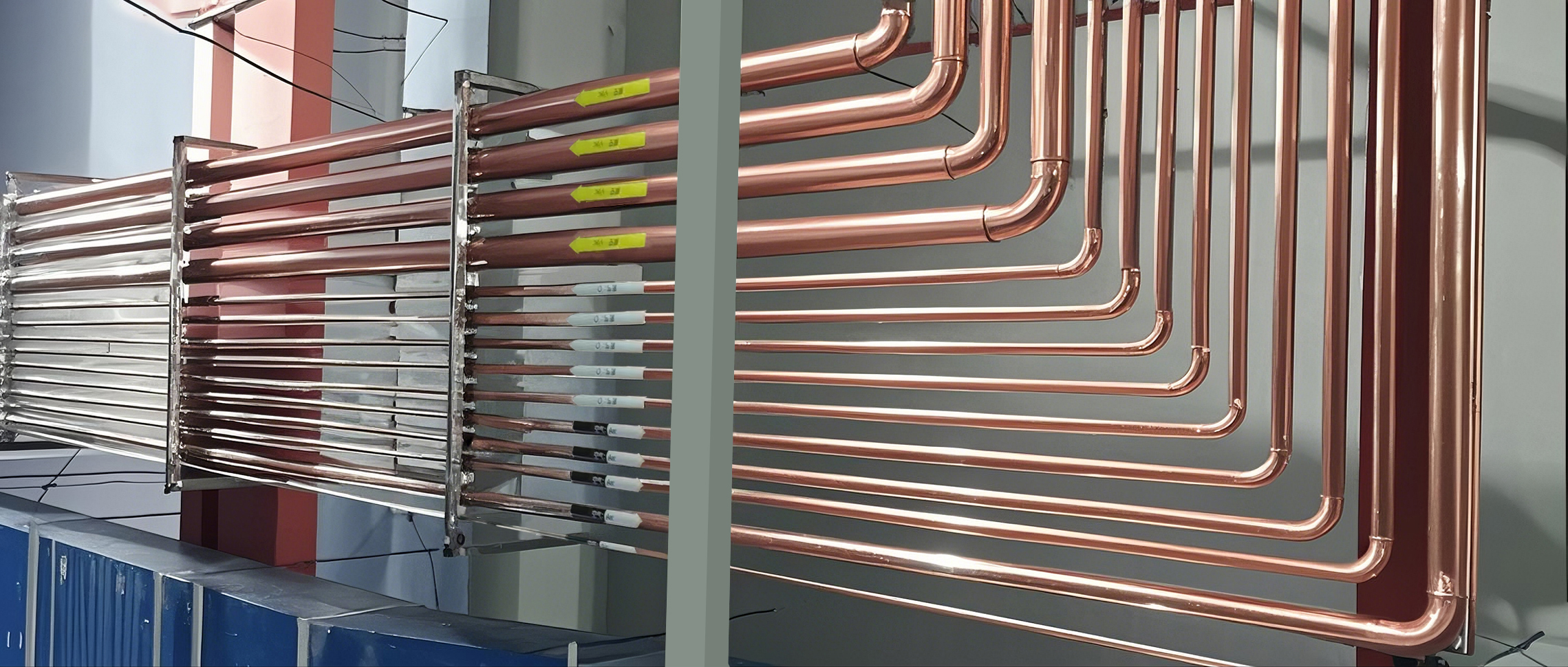

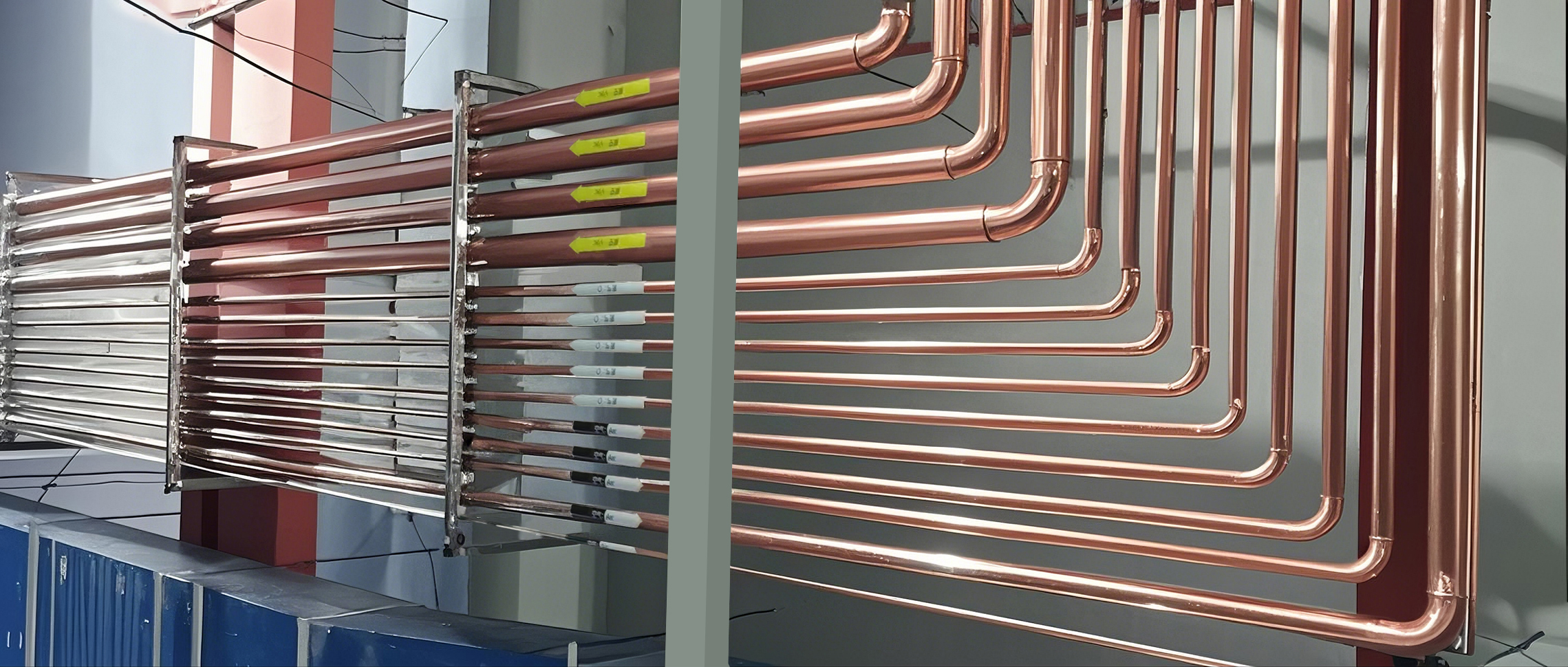

Copper Pipeline Installation Standards

Medical gas lines often use copper because it naturally fights bacteria growth and lasts a long time without corroding. When installing copper pipes for medical gases, there are strict rules about things like pipe size, how welds need to be done, and what tests must pass before putting them into service. Following these guidelines keeps everything working properly and prevents dangerous situations. Stick to the copper pipe standards and hospitals can avoid those costly leaks that disrupt operations and put patients at risk. Good installation work makes all the difference when it comes to keeping medical gas systems running safely day after day.

Zone Valve Safety Mechanisms

Zone valves play a vital role in medical gas systems as important safety features. These devices let technicians shut off certain parts of the gas line when there's an emergency situation or when regular maintenance work needs to happen. Putting these valves in the right spots around the facility makes all the difference for both safety and how smoothly operations run day to day. Maintenance crews should check these valves regularly, maybe every six months or so, to make sure they'll actually work when someone really needs them during a critical moment. When hospital staff understand exactly how these valves operate, it creates better preparedness across the whole building, especially in those high pressure situations where seconds count.

Pressure Regulation Techniques

Getting medical gases delivered properly depends heavily on good pressure regulation techniques. These methods keep gases flowing at safe levels so patients get exactly what they need without risk. Pressure regulators and those safety relief valves work together to protect equipment from damage when things go wrong. When staff check pressure readings regularly and tweak settings as needed, it stops problems before they happen and keeps everything running within legal requirements. Medical facilities that stick with proper pressure management practices end up with systems that last longer, cost less to maintain, and most importantly, provide consistent care without unexpected failures during critical moments.

NFPA 99 Compliance for Medical Gas Systems

Regulatory Requirements Overview

The National Fire Protection Association's standard 99 lays down the basics for keeping medical gas systems both safe and dependable through its detailed safety requirements. These rules really matter because they help keep everyone in the hospital safe from dangers linked to things like oxygen tanks or anesthesia gases. Following NFPA 99 isn't just about checking boxes for regulations either. Hospitals need to stick to these standards if they want to keep their accreditation status intact while delivering care without putting anyone at risk. Most hospitals actually get inspected several times a year by third party experts who check everything from pipe installations to emergency shut off valves. Any problems found during these checks can lead to serious consequences for patient safety down the road.

Alarm System Implementation

Medical gas systems wouldn't be safe without their alarm systems constantly watching for problems. These alarms help keep patients safe because they go off right away when something goes wrong, like if there's a gas leak or pressure drops suddenly. When an alarm works properly, it gives staff time to react before things get dangerous. That's why hospitals need to test these alarms regularly. Nobody wants to find out during an emergency that the alarms aren't working correctly. Maintenance checks make sure everything functions as it should so staff can respond quickly whenever issues arise.

Verification Protocols

Verification protocols serve as regular checks to make sure all parts of a medical gas system comply with required safety standards. The whole process needs detailed records kept for each check completed, which helps track who did what when and shows we're following the rules set by health authorities. When hospitals stick to strict verification schedules, they catch small problems before these turn into major headaches down the road. For instance, a minor leak detected during routine checks can prevent dangerous oxygen shortages later. These ongoing inspections aren't just bureaucratic requirements but actual life-saving practices that keep medical gas systems working properly across hospitals and clinics, ultimately protecting patients receiving treatment.

Emergency Procedures for Gas Pipeline Systems

Shutdown Protocols During Crisis

Creating good shutdown plans helps cut down dangers during emergencies with medical gas systems like oxygen or anesthesia lines. The rules need to tell people exactly when and how to turn off parts of the pipeline network without putting anyone at risk. When hospitals have solid written procedures, they keep everyone safe while protecting the actual gas delivery infrastructure too. Training staff thoroughly on what to do makes all the difference. People who know their stuff respond faster when something goes wrong, which means better outcomes for everyone involved. This kind of preparation really matters because it keeps things running smoothly even when regular operations get thrown into chaos unexpectedly.

Backup Oxygen Supply Management

A good backup oxygen supply matters a lot, particularly in intensive care units where patients depend on continuous oxygen delivery. Medical facilities rely heavily on their gas systems, so when oxygen runs out or gets interrupted, it can put lives at risk. That's why hospitals need to check those backup systems regularly and run emergency drills now and then to stay prepared. Getting how these backup systems work together with the main ones during crises makes all the difference. When everything connects properly, doctors and nurses don't have to worry about running out mid-procedure. Taking this whole approach seriously helps protect patients from harm while giving healthcare workers peace of mind knowing they can focus on treating rather than fixing equipment failures.

Maintenance Strategies for Medical Gas Systems

Leak Testing Methodology

Testing for leaks remains one of the most important maintenance tasks when it comes to keeping medical gas systems safe and running efficiently. Finding those leaks early matters a lot since missing them can create serious safety problems plus mess up operations across the board. Pressure decay testing works well here, giving technicians a good look at system integrity through simple measurements of how pressure drops over time in sealed environments. What makes this method stand out? It catches tiny leaks long before they turn into bigger headaches down the road. Regular checkups for these leaks help avoid surprise shutdowns while protecting patients who depend on steady access to vital gases like oxygen throughout their treatments.

Preventive Maintenance Scheduling

Keeping medical gas systems running smoothly requires regular preventive maintenance that doesn't get overlooked. Good maintenance programs typically involve checking equipment regularly, keeping things clean, and swapping out parts when needed according to manufacturer guidelines. When facilities stick to these plans, they keep everything working properly and cut down on unexpected breakdowns that could endanger patients. Detailed maintenance logs matter just as much as the actual work itself. These records help meet regulatory requirements for sure, but they also tell facility managers where problems tend to pop up again and again. Looking at past maintenance data helps technicians prepare better for future repairs and spot patterns that might indicate bigger system issues before they become critical failures.