Compressed Gas Systems vs. Liquid Oxygen Plants

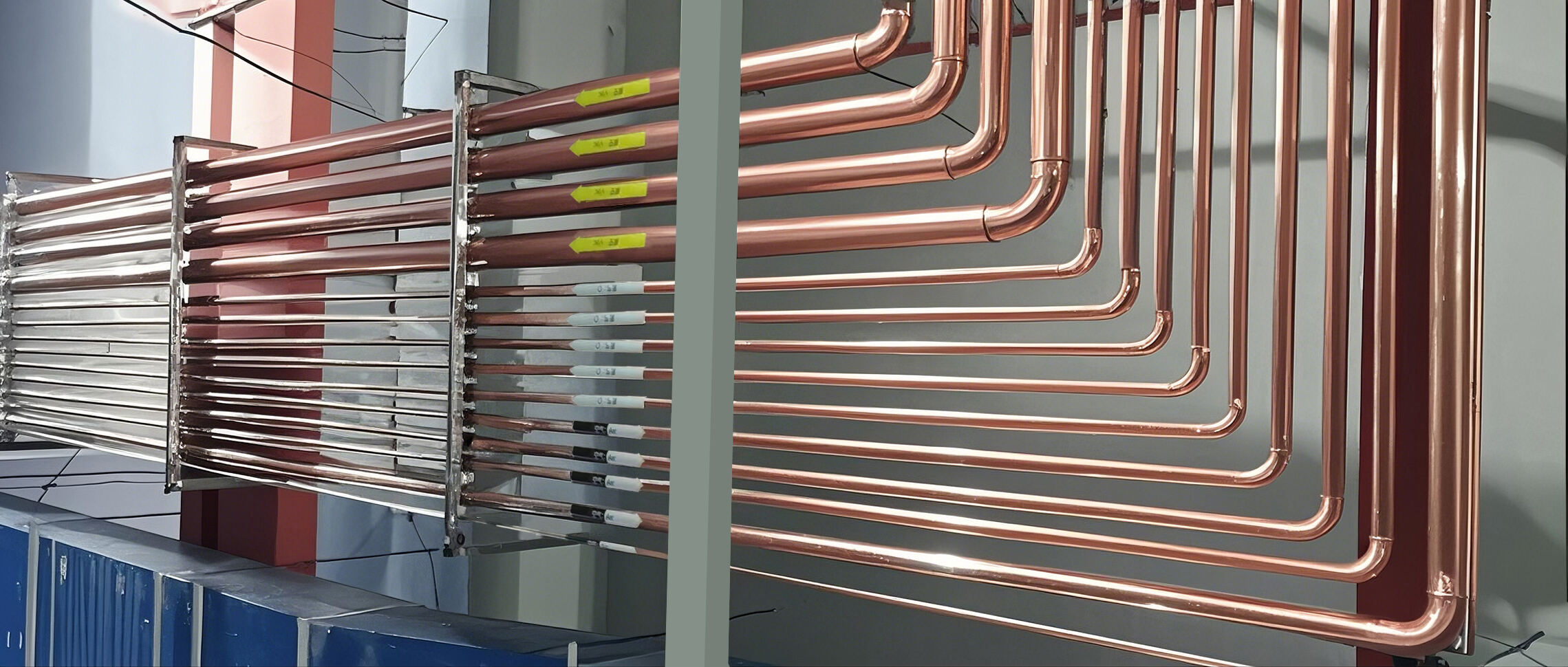

The two most basic device systems for the commercial production of medical gases are compressed gas systems and liquid oxygen plants, with each providing its own means of operations. Over the counter supply of O 2 may be available as they are produced by the compressed gas system, which can concentrate O 2 from room air, thus providing an immediate and cheaper alternative if the facility has need to provide an alternative source of oxygen in a short period of time and moderate proportion of oxygen. Liquid oxygen plants, on the contrary, can store more in comparison and are generally more efficient as liquid form is more concentrated and can be vaporized with greater volume if necessary. Compressed gas systems dominate the market, accounting for 60%, owing to the easy availability and cost-efficiency, while liquid oxygen plants are utilized in approximately 40% of the market, especially in hospitals consuming large volumes of oxygen continuously due to extensive infrastructure.

Portable Oxygen Concentrators: Mobility & Efficiency

The importance of POCs for home care Portable oxygen concentrators have become an essential device in home health care because of its convenience and effectiveness . These machines function by purifying the surrounding air to provide pure oxygen, suitable for patients with respiratory diseases in need of portable respiratory therapy. Models differ by flow rate, with some providing a maximum flow rate of up to 3 liters per minute, which facilitates the choice of patient care. Battery life is crucial and many have the capacity to be used for anywhere between 4 to 8 hours with a single charge as claimed by the manufacturers. Furthermore, these concentrators are typically compact in size and have been designed with patient portability in mind, typically weighing less than 5 lbs., and including simple user interfaces. Performance is evaluated on the basis of oxygen yield per power input, to guarantee at least essential oxygen consumption with the lowest possible rate of energy consumption.

Stationary vs. Ambulatory Oxygen Making Machines

Bubble portable oxygen machines and home stationary units are not used for the same thing or the same kind of patient and not for the same medical necessity either. Stationary concentrators are for high volume oxygen users, and are available for use at home or clinics. They also offer better flow rates and are generally stationary at home. Advanced systems, on the other hand, are less heavy and bulky and most comfortable, easier to be carried by the patient, permitting him to move and keep living a normal life. Patient studies indicate that outpatients prefer ambulatory devices because they are portable and do not intrude on daily activities. However, current developments have made the boundaries of distinction between stationary stationary units with portable elements and vice versa, which conveys progress in bettering patient comfort without compromising any therapeutic benefit.

Key Selection Criteria for Oxygen Supply Systems

Flow Rate Requirements: Matching Liters/Minute to Needs

The oxygen flow rate of an oxygen supply system is what s needed for an effective medical treatment to be received by a particular patient. The flow rate is usually ordered in liters per minutes (LPM) and the usual range is between 1 and 10 LPM according to the indication. Provider The patient's oxygen level, activity level, and overall treatment plan help determine the LPM needed. For patients with severe respiratory issues, like COPD, a higher flow rate might be needed. It has been demonstrated by several reports that incorrect flow settings may have an adverse impact on patient outcomes and the proper calibration is therefore crucial.

Portability Factors: Weight and Mobility Considerations

For oxygen concentrator, weight and mobility must be came into consideration, particularly for the outport users who have needed to move frequently. Portable devices are generally “lightweight” (e.g., less than ten pounds) and constructed with features that promote patient mobility (e.g., small profile and convenient carry handles). A heightened concern is that users constantly depart home for activities and trips. Feedback has shown that users would like lighter systems for use, reducing inconvenience of use in their daily life. Accordingly balancing the weight and portability of the GBG with the user's daily activities is critical to meet the convenience factor.

Power Supply Options: AC vs. Battery-Operated Systems

Selection of AC or battery operated oxygen delivery systems is a balance between their respective advantages and disadvantages with respect to reliability and access. AC systems provide continuous power and are convenient for patients at rest in the home environment on the other hand does not have the versatility needed to be ambulatory. On the other hand, battery-powered systems offer mobile solutions that are vital to traveling users and the most relevant concerns are battery lifetime and recharge rates. When seeking expert advice, the most suitable power supply for a device should be determined based on common usage environments, matching the selected system to the patient's lifestyle and medical needs.

Evaluating Oxygen Concentration and Delivery Efficiency

Oxygen Purity Standards (87%-99% Concentration)

Keeping the oxygen purity within a concentration of 87%-99% is necessary for many medical applications. This requirement is to keep the patient's oxygenation at a level that minimizes the risks of hypoxia. This is because regulatory agencies – such as the U.S. Food and Drug Administration (FDA) and the European Medicines Agency (EMA) – impose such criteria to ensure the safety and efficacy of therapies for patients. Non-adherence has serious attendant consequences, as is apparent from analysis which demonstrates an association between inadequate oxygen delivery and poor health outcomes. For example, worldwide guidelines suggest that maintaining oxygen purity at a high level is essential in receiving patient treatment, with periodic monitoring used to prevent complications and to get the best oxygenation.

Pulse vs. Continuous Flow Delivery Mechanisms

There are two main methods of delivering oxygen, which have different health effects. Pulse flow provides oxygen when the patient inhales and this saves on oxygen and increases portability. Continuous flow, on the other hand, is a constant delivery of oxygen and is appropriate for any patient in need of a constant oxygen supply due to particularly severe respiratory conditions. In clinical trials, these patient preferences tend to be self-consistent with mobility and activity levels. Pulse flow systems are going to be the best bet for the more active of individuals, as they tend to be less bulky and weigh less. "Continuous flow systems are used for more static patients who have a more permanent oxygen requirement," he said.

Humidification Needs for Long-Term Medical Use

Humidification may help to improve patient comfort and well-being when the therapy is of long-term duration. Good humidification helps avoid dry air which can cause irritation or worsen nasal and throat problems. [0002] Medical guidelines support the use of humidification systems concomitantly with oxygen ventilators and generators, in particular for patients undergoing prolonged oxygen therapy. Studies have shown that when the right humidification is applied, patient recovery can be improved, resulting in fewer complications, such as nosebleeds or dry mouth. Research has proven the value of these systems, showing increased general respiratory health and enhancing the quality of oxygen supply systems with long-term use.

Safety and Compliance in Oxygen Generator Projects

Certifications for Medical Gas Production Equipment

Make sure you are aware of the importance of medical gas production equipment certification for patient safety and oxygen system dependability. Compliance generally will begin by achieving a few important certifications such as ISO 13485 (quality management systems for medical devices) and CE marking (a conformity marking where the product meets EU health, safety, and environmental protection product regulations for those sold within the European Economic Area). These certifications are important in ensuring that the equipment conforms to strict medical gas specifications, and is vital to delivering patient care. Advised groups like the International Organization for Standardization (ISO) and European Conformity (CE) both help to establish these guidelines, and offer certifications that the equipment has been constructed following the global standards for safety.

Fire Safety Protocols for Oxygen-Rich Environments

In oxygen-enriched atmospheres, particularly in healthcare facilities, it is also important to follow fire precautions. These procedures are designed to reduce the risk of fire of and from the flammable characteristic of oxygen. Numbers show that mishaped oxygen systems have high tendency to cause more fire outbreajs, stressed the attention on the importance of safety regulations. Preventive measures adhered to include regular checks and appropriate storage of oxygen tanks, and ventilating properly. Furthermore, as healthcare providers will be responsible to use these measures, they also should be trained on these protocols, so they will be familiar with how to handle possible fire hazards effectively. Training may include hands-on fire drills and discussions on the specific hazards presented by oxygen-rich environments.

Oxygen Conserving Device (OCD) Integration

Oxygen conserving devices (OCD) are essential to maximising the efficient use of oxygen and have a significant impact on patient improvement. These apparatuses are based on the principle of delivering oxygen exclusively during inspiration, thus enabling the gas to be used more efficiently and allowing longer periods to elapse between refilI operations. Combining OCDs with existing oxygen systems has many advantages, such as less waste of oxygen and longer use of the product. Studies indicate that they are effective: OCDs can increase tubing life and extend the use of portable oxygen i and that is important to patients’ mobile and home care. Their ability to maximize oxygen delivery results in increased patient mobility and convenience as well as savings in the cost of oxygen refills by reducing refill frequency.

Operational Considerations for Oxygen Plants

Noise Level Thresholds in Clinical Settings

At the time of installation of oxygen plants in the health-care facilities, it is important that the noise level should be within the acceptable range to make it comfortable for the patient and staff and efficient for their performance. Too much noise can disturb the healing atmosphere and add to the already high level of stress for both patients and staff. Experts say hospital noise levels should not exceed 45 decibels during the day and 35 decibels at night, a guideline endorsed by the World Health Organization. Studies have shown that patients are more restless and dissatisfied in noisy spaces, emphasizing the significance of acoustic control in healthcare facilities.

Maintenance Routines for System Longevity

PRESERVING THE LIFE OF OXYGEN SUPPLY SYSTEMS An oxygen supply system will last longer with good preventative maintenance. Scheduled maintenance and proper parts replacement can help prevent failure and promote a longer life for the system. Research has shown that it is not unusual for a properly cared for system to last upwards of 15 years while poorly cared for systems may not even make it to half that age. When maintenance is ignored, it may result in expensive equipment repairs that jeopardize patient care, and also erode the dependability of oxygen supply and healthcare service at large.

Warranty and Service Network Accessibility

It's hard to overstate the value of service network and warranty in choosing an oxygen system. With such extensive warranties, usually 2-5 years, you would be safeguarded against unplanned system failures and maintenance misjudgments. The availability and reliability of a service network should also be considered. A strong network ensures quick resolution of technical malfunctions preventing comprehensive support of the system. They are useful for health service practitioners in ensuring sustainable decisions for continued supplies of oxygen and maximum patients' care.

Table of Contents

- Compressed Gas Systems vs. Liquid Oxygen Plants

- Portable Oxygen Concentrators: Mobility & Efficiency

- Stationary vs. Ambulatory Oxygen Making Machines

- Key Selection Criteria for Oxygen Supply Systems

- Evaluating Oxygen Concentration and Delivery Efficiency

- Safety and Compliance in Oxygen Generator Projects

- Operational Considerations for Oxygen Plants