Full disclosure of the birth of medical oxygen

Revealing the Entire Birth Process of Medical Oxygen

The birth of medical oxygen represents a fusion of precise technology and life safety. Transforming from air to "life-saving gas" requires undergoing three core processes (cryogenic separation, membrane separation, and pressure swing adsorption), followed by rigorous sterilization filtration. Exclusive analysis by Today's Headline—the hardcore technology behind every breath of medical oxygen!

I. Three Major Preparation Processes: Transformation from Air to High-Purity Oxygen

1. Cryogenic Separation Method: The "Song of Ice and Fire" at -196°C

- Principle: Utilizes the boiling point difference between oxygen (-183°C) and nitrogen (-196°C). Air is compressed, liquefied, and then gradually heated to separate liquid oxygen.

- Purity: ≥99.5%, meeting the highest medical oxygen standards (as required by the Chinese Pharmacopoeia).

- Key Equipment: Air separation tower, liquid oxygen pump, and low-temperature storage tank (-183°C insulation).

- Application: Main source for central oxygen supply systems in large hospitals and bottled medical oxygen. Cryogenic separation accounts for over 90% of the global medical oxygen supply but requires high equipment investment and energy consumption, making it suitable only for large-scale production.

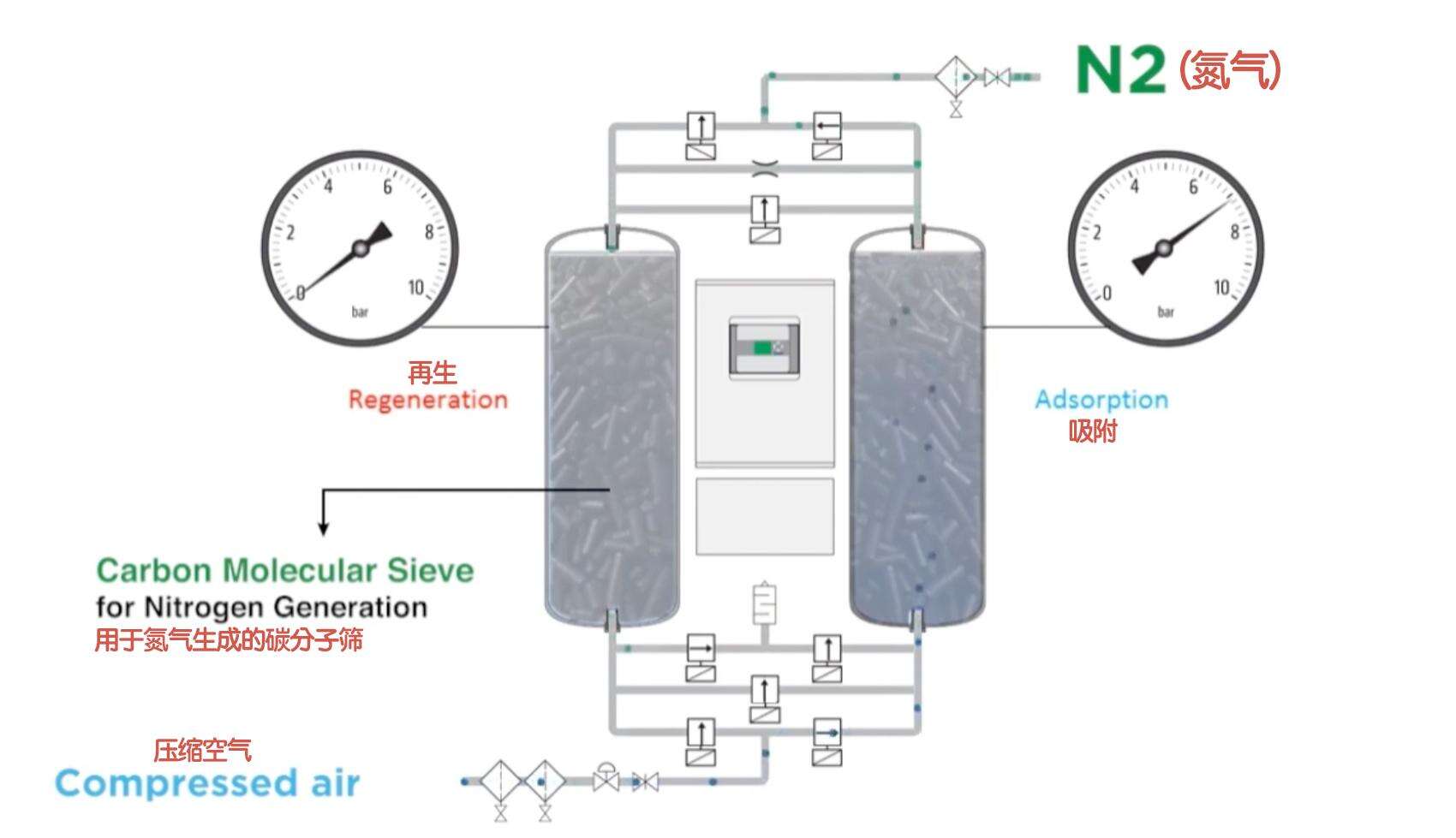

2. Pressure Swing Adsorption (PSA): Molecular Sieve's "Intelligent Screening"

- Principle: Compressed air passes through zeolite molecular sieves, where nitrogen is adsorbed, and oxygen is enriched and output (adsorption-desorption cycles occur).

- Purity: 90%–96% (oxygen-enriched air), suitable for home oxygen concentrators and hospital centralized oxygen supply.

-

Technological Upgrades:

- VPSA (Vacuum Pressure Swing Adsorption): Low-pressure adsorption + vacuum desorption, reducing energy consumption by 30%.

- Dual-Tower Alternation: One tower adsorbs and produces oxygen while the other desorbs and discharges nitrogen, enabling continuous oxygen supply.

- Note: Oxygen concentration in home oxygen concentrators decreases as flow rate increases (e.g., only 70% at 5L/min flow).

3. Membrane Separation Method: Nanoscale "Precise Penetration"

- Principle: Air passes through a polymer oxygen-enriching membrane, where oxygen molecules (diameter 0.346nm) permeate faster than nitrogen (0.364nm), achieving separation.

- Purity: 30%–50% (single-stage), requiring secondary purification to reach 90%.

- Breakthrough: PSA + Membrane Separation Hybrid Technology—first uses PSA to produce 90% oxygen-enriched air, then employs membrane separation to remove argon, increasing concentration to 99.5%. Membrane separation advantages: No moving parts, silent operation, suitable for vehicle emergency oxygen generation.

Comparison of the Three Processes

|

Process |

Purity Range |

Applicable Scenarios |

Cost Characteristics |

|

Cryogenic Separation |

≥99.5% |

Hospital central oxygen supply, liquid oxygen tanks |

High investment, low unit production cost |

|

Pressure Swing Adsorption |

90%–96% |

Home oxygen concentrators, small hospitals |

Moderate investment, flexible |

|

Membrane Separation |

30%–50% |

Vehicle/portable oxygen generation |

Low energy consumption, low purity |

II. How Does an Oxygen Generator Produce Oxygen? A 4-Step Breakdown of the Core Process

Taking Yite Medical's medical molecular sieve oxygen generator as an example, let's unveil the microscopic battlefield of "air into oxygen":

1. Compression and Pressurization—Creating a "High-Pressure Battlefield"

- An oil-free compressor pressurizes air to 0.2–0.3 MPa (equivalent to 20–30 meters underwater pressure), forcing gas molecules to collide densely and creating conditions for molecular sieve adsorption.

- Silent design: A DC motor keeps noise ≤45 decibels (hospital-grade silence), avoiding patient disturbance.

2. Air Purification—Removing "Enemy Impurities"

- Initial screening: Air undergoes multi-stage filtration (primary filter intercepts pollen and dust; high-efficiency filter blocks bacteria >0.3μm and PM2.5).

- Deep purification: A refrigerated dryer removes moisture, and activated carbon adsorbs oil mist, ensuring "pure and pollution-free" air.

3. Molecular Sieve Adsorption—Nitrogen and Oxygen "Separation Siege"

- Adsorption stage: Compressed air enters an adsorption tower filled with zeolite molecular sieves. Nitrogen (molecular diameter 3.64Å) is strongly adsorbed by the molecular sieve's micropores (3–5Å), while oxygen (3.46Å) freely passes through, achieving enrichment.

- Dual-tower strategy: Two towers operate alternately—

- Tower A adsorbs and continuously produces oxygen for 30–60 seconds.

- Tower B desorbs, rapidly depressurizing to release nitrogen and thoroughly clearing the field with oxygen counter-blowing.

4. Oxygen Purification and Output—Final "Sterile Purification"

- Sterilization filtration: Oxygen-enriched gas passes through a 0.22μm sterilizing filter membrane (intercepting 99.99% of bacteria), meeting medical sterile standards.

- Humidification and temperature adjustment: Oxygen passes through a humidifier bottle (with distilled water) to moisten and avoid respiratory mucosa damage.

Medical-Grade "Combat Standards": Stricter Than Ordinary Oxygen Concentrators

|

Indicator |

Medical Molecular Sieve Oxygen Generator |

Ordinary Home Oxygen Concentrator |

|

Oxygen Concentration |

(National standard mandates >90%) |

Usually 60%–90% |

|

Sterility Assurance |

0.22μm sterilizing filter membrane + Class 10,000 clean environment |

No strict sterilization requirements |

|

Safety Monitoring |

Real-time oxygen concentration sensor + fault alarm system |

Some lack concentration monitoring |

|

Noise Control |

≤60dB (hospital-grade silence) |

Often reaches 50–65dB |

Why Must Oxygen Concentration Be Above 90%?

Oxygen concentrations below 90% cannot meet the blood oxygen elevation needs of patients with chronic obstructive pulmonary disease (COPD) or heart failure, while concentrations >96% may pose explosion risks.

- Fatal Risk Points: If oxygen bacterial content before filtration exceeds 10 CFU/100ml or the filter membrane is damaged, it can cause pulmonary infections in patients.

- Medical Contraindications: These situations prohibit "participation"—

- Prohibited Users: Patients with a history of oxygen toxicity or oxygen allergies (rare but fatal).

- Environmental Warnings: Strictly prohibit use near open flames (oxygen is combustible), and maintain humidifier bottle water level at 1/2 (to prevent backflow failures).

Conclusion: The Technological Barriers of Medical-Grade Oxygen Generation

Medical molecular sieve oxygen generators convert ordinary air into life-saving "oxygen ammunition" through three layers of technology: precise molecular sieve adsorption, dual-tower circulation tactics, and sterile-grade purification.^[31]^ Their core value lies in:

- Life-Saving Purity: 90%–96% oxygen concentration precisely matches pathological needs.

- Safety Redundancy: Real-time monitoring + dual filtration eliminate infection risks.

- Sustained Combat Effectiveness: 20,000-hour molecular sieve lifespan ensures long-term oxygen therapy.